In the competitive landscape of the yeast fermentation industry, rapid and accurate quality assessment is crucial for optimizing production and enhancing commercial competitiveness.

Researchers from Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT), Chinese Academy of Sciences (CAS) and Tianjin Agricultural College have introduced an innovative approach utilizing single-cell Raman spectroscopy (SCRS) technology. This method promises to revolutionize the yeast industry by offering a rapid, cost-effective, and precise method to evaluate yeast's metabolic activity and freeze resistance.

Results of the study were published online in Synthetic and Systems Biotechnology on Sep. 11.

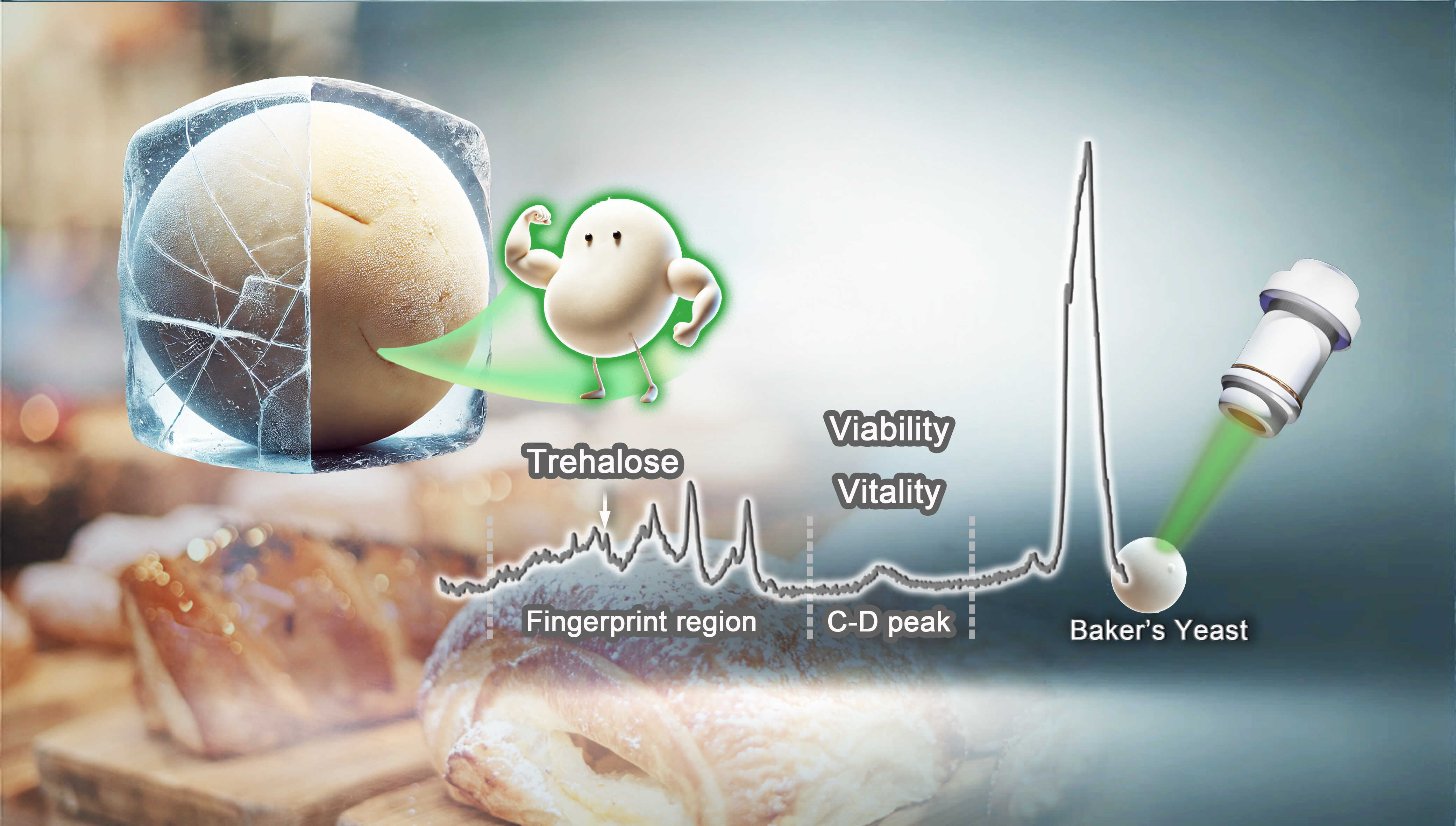

Revolutionary Single-Cell Raman Spectroscopy Technology for Baker's Yeast Quality Assessment. (Image by LIU Yang)

"The yeast market is rife with inconsistency in product quality," notes Prof. ZHANG Jia, corresponding author of the paper from the Single-Cell Center at QIBEBT. "Our SCRS technology provides a rapid and precise assessment of yeast quality, a critical factor for producers and consumers alike."

Baker's yeast plays a crucial role in food production, yet assessing its quality has traditionally involved time-consuming and costly methods, such as cell culture and biochemical assays, that lack the sensitivity and accuracy required in today's competitive market.

The new SCRS method incorporates D2O probes to deliver accurate measurements of metabolic activity of baker's yeast cells, such as cell viability and overall cell vitality, at both population and single-cell levels. By utilizing fingerprint region of the Raman spectrum, this approach enables precise analysis of intracellular trehalose content, which is crucial for assessing cells’ freeze resistance.

A significant advantage of this technology is its ability to detect viable but non-culturable (VBNC) cells, which are frequently overlooked by conventional methods.

"We can now analyze yeast cells in just a few hours, a process that used to take days," says Prof. SUN Xi from Tianjin Agricultural College. The new method offers a tenfold increase in speed and reduces costs to just a tenth of what traditional methods require.

"This technology not only benefits yeast producers with a powerful quality control tool but also ensures consumers receive a higher quality product," adds Prof. ZHANG.

The research team is looking to the future with plans to partner with industry leaders. Their goal is to establish a standardized, comprehensive technical service platform, which will drive quality standardization across the yeast industry, ensuring a more reliable and consistent product for all.